- Home

- Yaskawa

- AC Servo Motor

- SGMGV-20ADA61 HAAS 93-1924

Repair for Yaskawa SGMGV-20ADA61 HAAS 93-1924

AC Servo Motor

ID: 17759

| Buy | Not available |

| Repair | from € 700.00 |

| Exchange | Not available |

Repair of HAAS HP Vector Drive and HAAS Servo Amplifiers

HAAS HP Vector Drive and HAAS Servo Amplifier

Additionally, we also offer services for Yaskawa motors.

We specialize in the following series:

HAAS HP Vector Drives come in various power levels and configurations:

- HAAS Vector Drive example model: 20HP 32-5559

- HAAS Vector Drive example model: 20/15 HP 69-1000

HAAS Servo Amplifiers come in different power levels and configurations:

- HAAS Servo Amplifier example model: 30A 32-5550J

- HAAS Servo Amplifier example model: 45A 32-3551J

Our repair process is preventative and includes a series of steps aimed at ensuring a high quality of repair.

Failure analysis and localization

What can you do?

Failures in Vector Drives and Servo Amplifiers

Possible solutions and tips

- Try replacing the motor.

- Check cable connections.

- Run in jog mode without load.

If these measures do not help, the error is usually in the power stage of the drive module.

More error messages can be found in the alarm list available for download at the end of this page.

Possible solutions and tips

- Warm up the device with an external source. If it turns on, it usually indicates a weak power supply that needs to be repaired.

- Check fuses.

- Check voltage supply of 3 x 200 or 220 volts, depending on the model.

More error messages can be found in the alarm list available for download at the end of this page.

Possible Solutions and Notes

Error Messages:

- Alarm #123: Spindle Drive Error

- Alarm #160: Undervoltage

Problem:

The machine reports an undervoltage, a common issue with many devices.

The customer sees on the machine control display that the target voltage

is not being reached – it should be around 320 volts DC.

Symptom Progression:

- Initially, the error occurs sporadically. The device often only works again, after warming up or after several power cycles. This is a typical approach used by many operators.

- Over time, the problem worsens: it takes longer for the device to work after being turned on, and more power cycles are needed.

Risk:

Repeated power cycling and improper handling can cause the

buffer electrolytic capacitors inside the device to explode.

In such cases, the device may fail completely and is often beyond repair.

Recommendation:

As soon as the error occurs, the device should be taken in for repair immediately

to avoid more severe damage.

Further error messages can be found in the alarm list available for download at the end of this page.

Possible solutions and tips

- Try replacing the motor.

- Check cable connections.

- Run in jog mode without load.

If these measures do not help, the error is usually in the power stage of the drive module.

More error messages can be found in the alarm list available for download at the end of this page.

Possible solutions and tips

- Warm up the device with an external source. If it turns on, it usually indicates a weak power supply that needs to be repaired.

- Check fuses.

- Check voltage supply of 3 x 200 or 220 volts, depending on the model.

More error messages can be found in the alarm list available for download at the end of this page.

Possible Solutions and Notes

Error Messages:

- Alarm #123: Spindle Drive Error

- Alarm #160: Undervoltage

Problem:

The machine reports an undervoltage, a common issue with many devices.

The customer sees on the machine control display that the target voltage

is not being reached – it should be around 320 volts DC.

Symptom Progression:

- Initially, the error occurs sporadically. The device often only works again, after warming up or after several power cycles. This is a typical approach used by many operators.

- Over time, the problem worsens: it takes longer for the device to work after being turned on, and more power cycles are needed.

Risk:

Repeated power cycling and improper handling can cause the

buffer electrolytic capacitors inside the device to explode.

In such cases, the device may fail completely and is often beyond repair.

Recommendation:

As soon as the error occurs, the device should be taken in for repair immediately

to avoid more severe damage.

Further error messages can be found in the alarm list available for download at the end of this page.

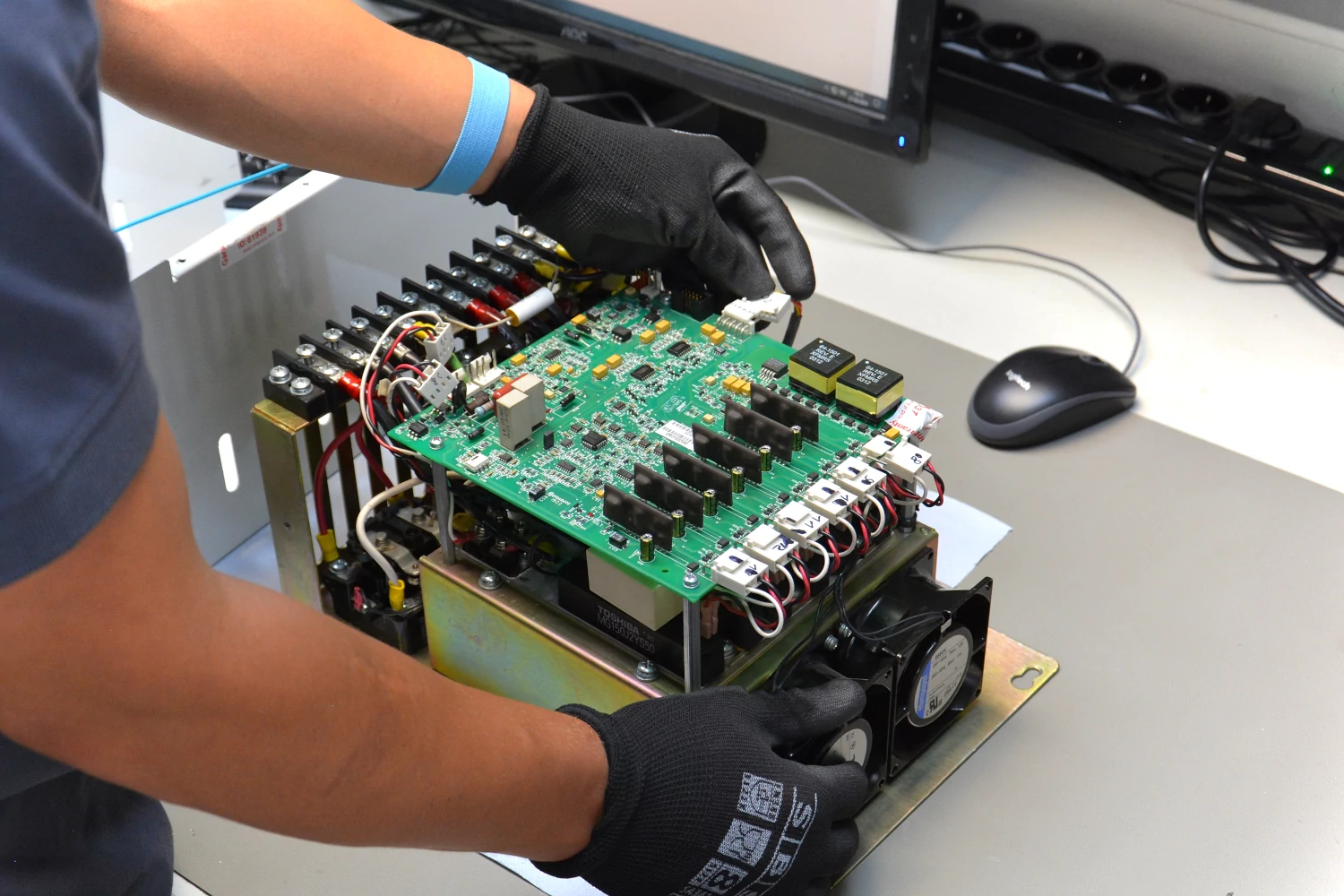

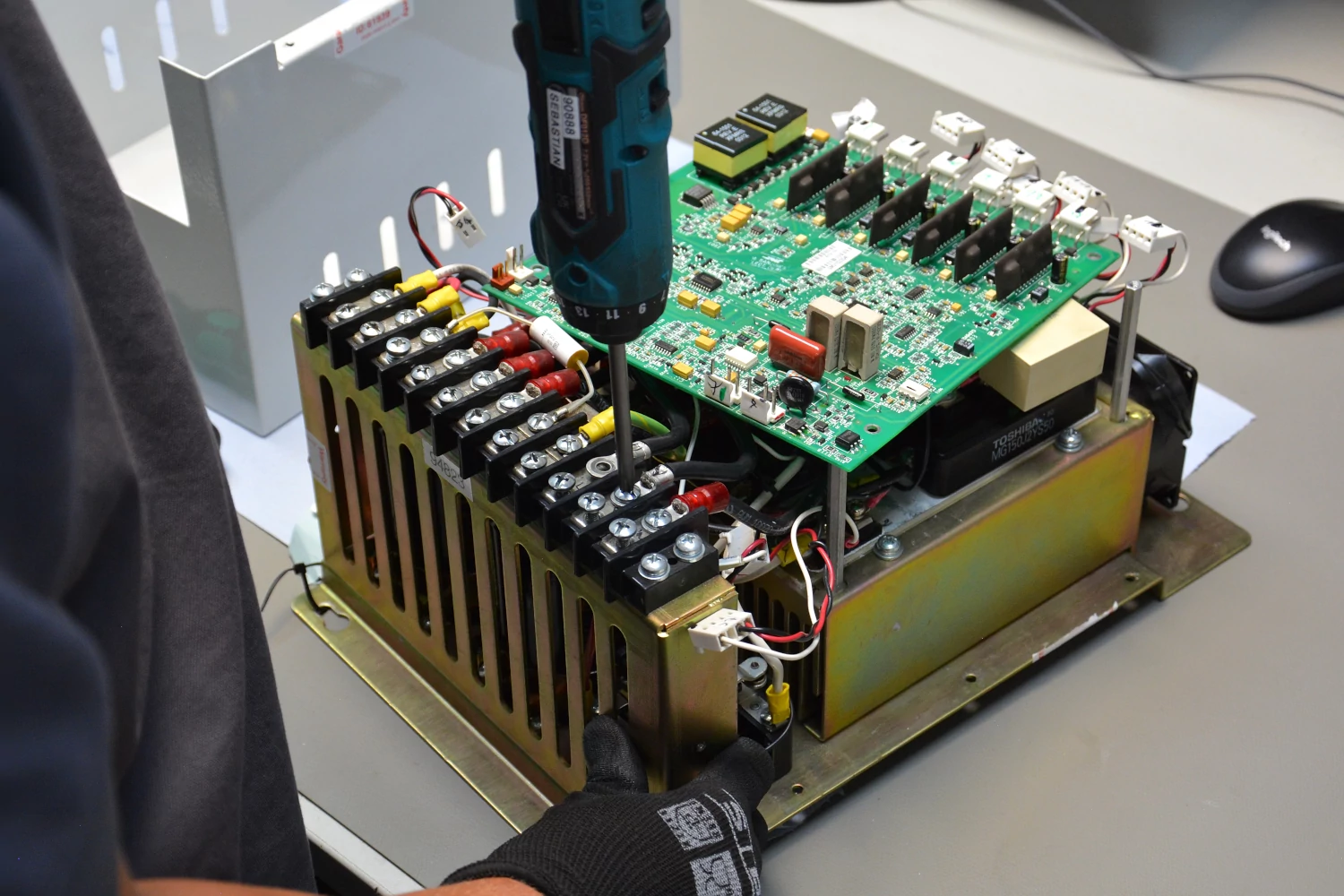

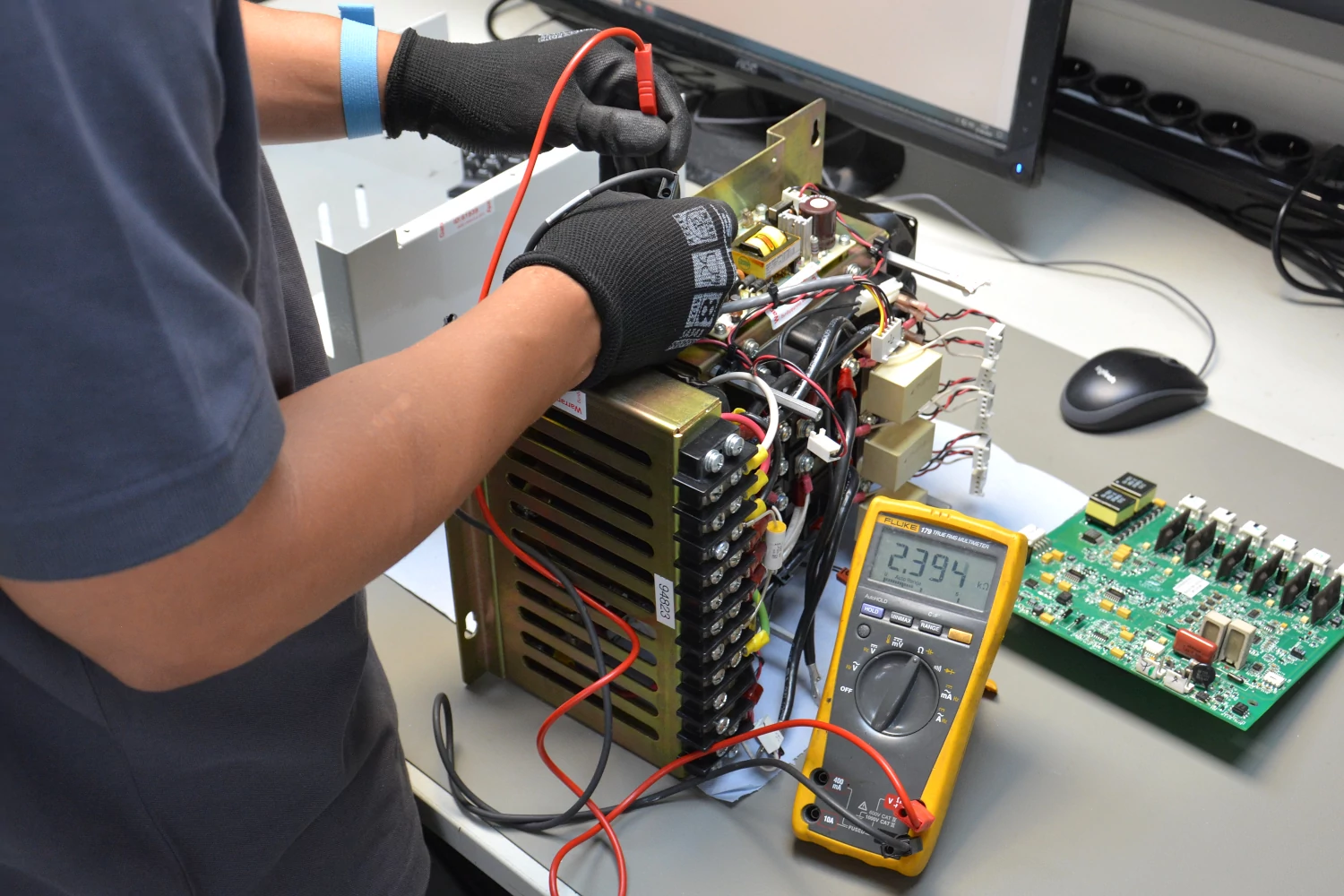

The typical process for repairing HAAS HP Vector Drive and HAAS Servo Amplifier

The repair process for Vector Drive or Servo Amplifier includes the following steps

- Intensive cleaning.

- Preventive overhaul - replacement of all necessary defective and worn-out parts.

- Comprehensive final and stress testing on our test benches, as well as on a dedicated HAAS machining center.

- Completion of documentation and checklists.

High-quality spare parts for high-quality repairs

In Vector Drives and Servo Amplifiers, we replace

- Electrolytic capacitors

- Large buffer capacitors

- Relays

- Current measurement modules

- Optocouplers

Additionally, we replace certain parts that have statistically shown to fail frequently after multiple repairs and have therefore been selected for replacement based on statistical data.

To counter shortages and discontinuations, we have processor-driven software solutions that monitor our inventory. We pre-order some parts in advance, and for serial repairs, we ensure sufficient spare parts for a year, allowing us to maintain a large stock at all times.

Quality and level of repair

We continuously expand our repair portfolio with new series

Since drive and power electronics are often discontinued prematurely, you may feel pressured to deliver replacements to your customers on time. We support you in analyzing shortages and work together to find optimal solutions.

The typical process includes:

- Development of test benches and procedures

- Organization of spare parts

- Preventive repair at the component level

- If necessary, redevelopment or re-engineering of modules or complete devices

Frequently Asked Questions

Motor repair

- New and fine adjustment of encoder/encoder systems

- As needed winding repair and balancing

- As needed connector repair or replacement

- For irreparable equipment, an alternative solution will be offered (e.g. replacement or sale)

Further information

Cost & Warranty

You can contact us in the following way:

Chat with our customer support, write us a message: info@industrypart.com or call us: +49 6251 9888430

We offer serial repairs for this product series

- Repair of many electronic assemblies according to standardized repair procedures with documentation.

- A larger repair capacity is possible for the same or similar orders

- Target group: machine manufacturers, service companies and distributors

Access to years of experience, specialists and equipment. Find out more about our series repairs