05.12.2025 by Viktor Siebert

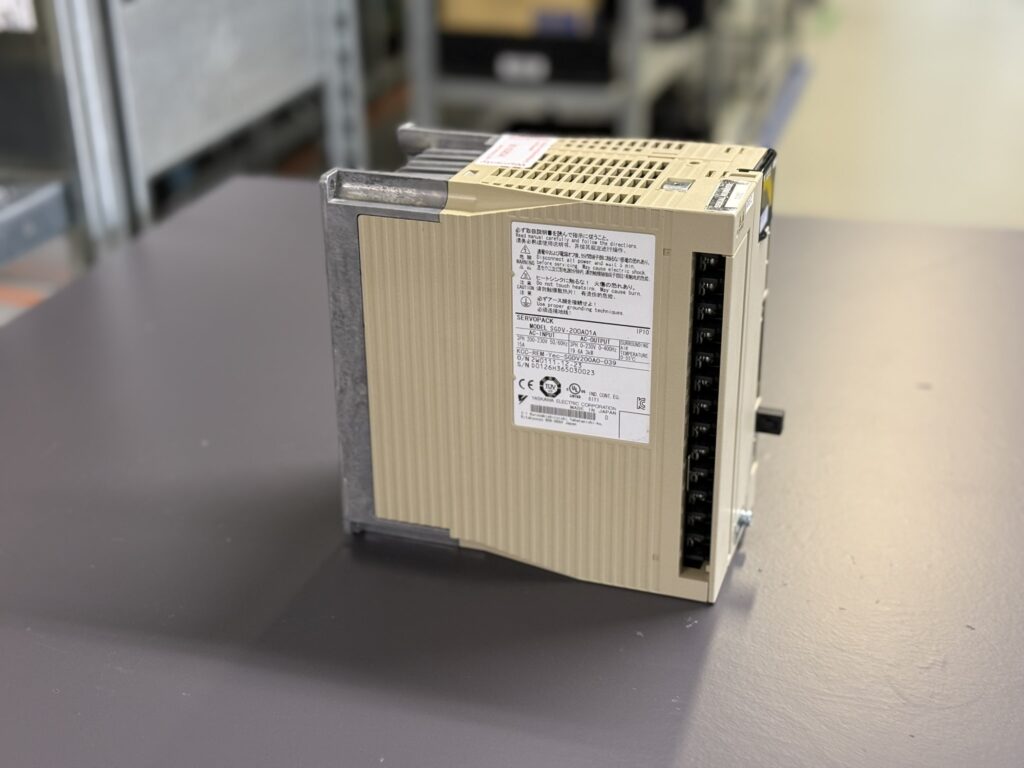

Repair of a Yaskawa SGDV-200A01A Servopack

Incoming Condition and Fault Description.

The Yaskawa SGDV-200A01A Servopack arrived with a clearly documented issue: “Fan does not rotate.” During initial testing our technician confirmed that the fan would start briefly, slow down and stop again. Immediately afterwards, the device triggered alarm A.7AB (Built-in Fan Stopped), making any further testing impossible without risking thermal damage.

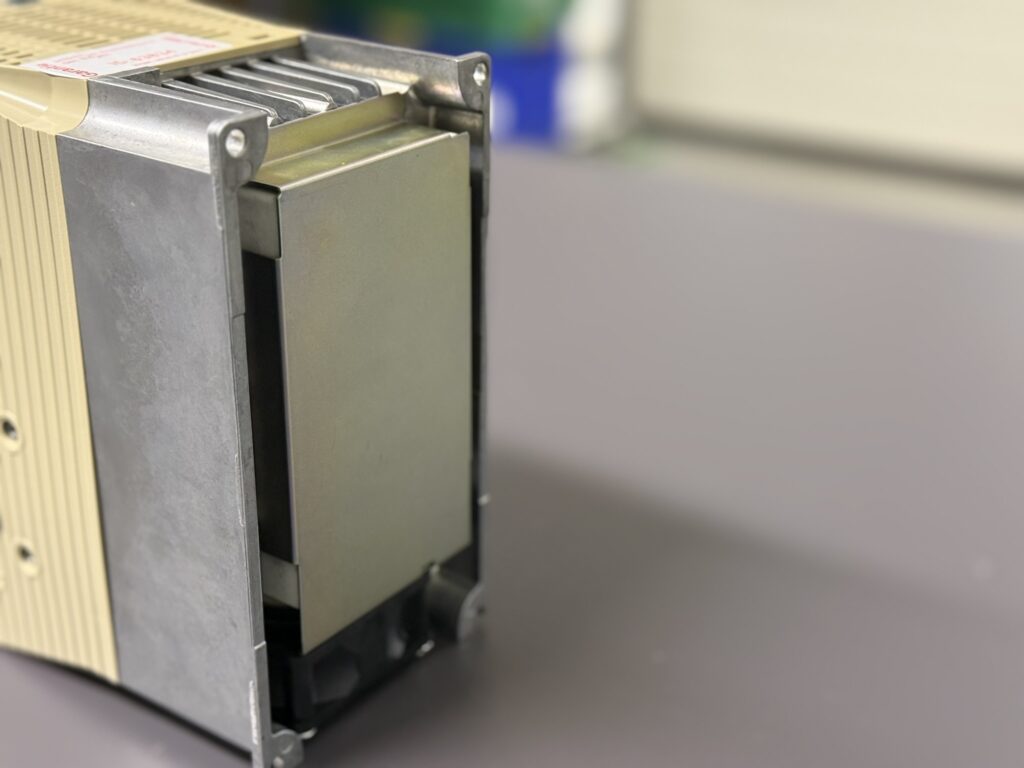

Already during external inspection, thermal discoloration around the heat-sink area was visible. This is typical for SGDV units operated for a longer time with a failing or intermittent fan. The Servopack attempts to limit output power, but during real machine operation dynamic loads quickly exceed safe thermal limits. This is exactly what happened here.

Disassembly and Initial Diagnosis

After opening the unit, the extent of the damage became clear. The cooling channel was heavily contaminated, the fan mechanism was intermittently blocking, and prolonged overheating had affected several components of the power stage. The temperature monitoring circuit still functioned but showed signs of thermal aging.

A detailed examination of the current paths revealed that multiple IGBT sections and gate-drive areas had suffered from repeated overheating. This is a well-known failure pattern: once the cooling airflow drops, the heat-sink temperature rises far beyond acceptable limits and the semiconductor components degrade rapidly.

Power Stage Repair

To restore full operational capability, the thermally damaged sections of the power stage were completely overhauled. This included:

• Replacement of all affected critical components

• Restoration of the gate-drive circuitry

• Renewal of thermal interfaces and heat-sink surfaces

• Full cleaning and reconditioning of the cooling channel

• Replacement of the defective built-in fan with an original-spec component

The repaired output stage was then thermally inspected and verified under controlled conditions. For Sigma-V units it is essential that the thermal transitions remain within tight tolerances, otherwise the device will trigger recurring alarms such as A.7A0 (Heat-sink Overtemperature) or A.100 (Overcurrent/IGBT Overheat).

Root Cause Analysis

The damage would have been entirely avoidable if the fan had been replaced earlier. The built-in fan is a known wear component. It runs continuously, often in dusty environments, gradually losing torque until thermal shutdowns occur.

The typical progression is:

- Fan loses torque → airflow decreases

- Heat-sink temperature increases

- Power components operate above design temperature

- IGBT modules and drivers begin to degrade

- Alarms A.7A0 or A.100 appear

- Complete failure of the Servopack follows

This process usually develops over months until the unit finally shuts down.

Final Testing and Approval

After the repair, the unit was deep-cleaned, the power stage recalibrated and the device was tested on our Yaskawa load test system. Multiple thermal cycles and dynamic load profiles were performed. The unit passed all functional and safety checks.

The fan now operates at full nominal speed and the power stage runs within perfectly stable thermal parameters. The Servopack was approved for return to the customer.

We additionally recommended regular fan maintenance, as replacing a low-cost fan is far more economical than repairing a thermally damaged power module.

Information about the mentioned Servopack: Yaskawa SGDV-200A01A Servopack

Further details on our Yaskawa repairs can be found here: Yaskawa Sigma V Repair

📞 Feel free to contact us if you have any questions regarding your Yaskawa drive technology. Our team will be happy to assist you.

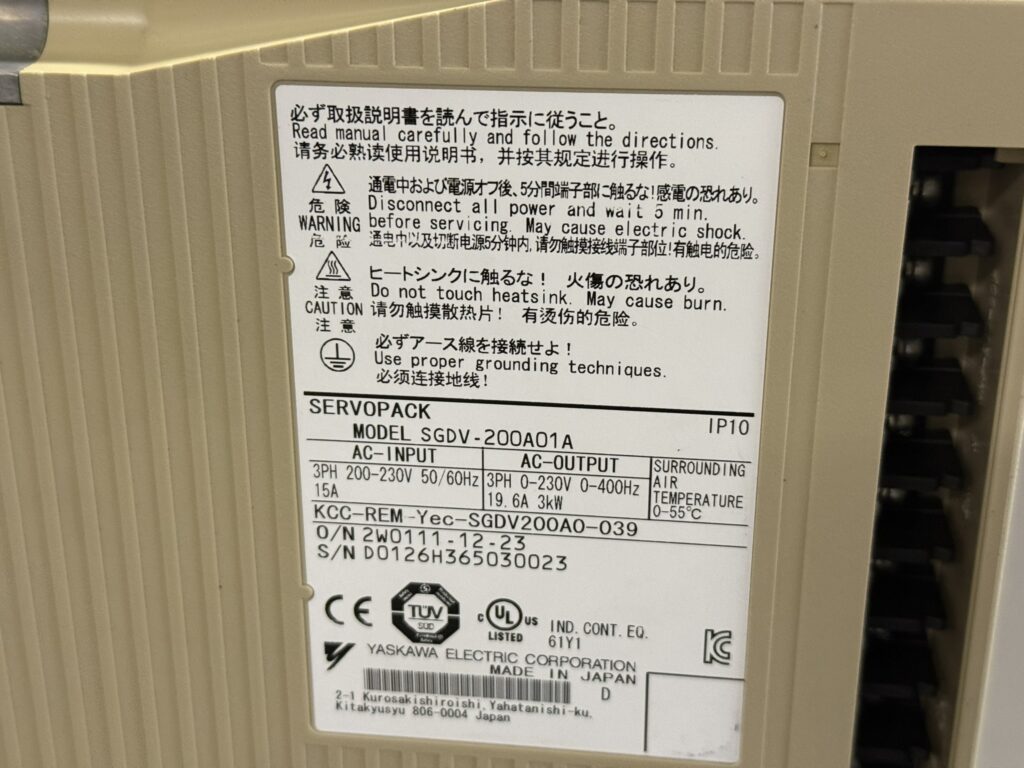

Device Specifications

| Category | Value |

|---|

| Model | SGDV-200A01A |

| Series | Sigma-V Servopack |

| Input Voltage | 3-phase 200–230 V AC, 50/60 Hz |

| Input Current | 15 A |

| Output Voltage | 0–230 V AC |

| Output Frequency | 0–400 Hz |

| Output Current | 19.6 A |

| Rated Power | 3 kW |

| Protection Class | IP10 |

| Ambient Temperature | 0–55 °C |

| Max. Humidity | 90%, non-condensing |

| Cooling | Built-in fan, air-cooled |

| Main Purpose | Control of Sigma-V servomotors |

| Manufacturer | Yaskawa Electric Corporation |

General Description

The Yaskawa SGDV-200A01A is a servo amplifier of the Sigma-V series, designed for precise drive control in machine tools, handling systems and positioning applications. The unit operates in the 200-V segment and provides a rated output power of 3 kW. The internal power stage is based on IGBT technology and requires continuous cooling by the built-in fan. A failure of the fan leads to thermal overload and can permanently damage the power stage.

The Servopack includes integrated diagnostic functions, status indicators, protective mechanisms and a comprehensive alarm management system. The most common fault for this model is A.7AB – Built-in Fan Stopped, indicating fan failure and preventing thermal damage.

Connections

| Connection | Description |

|---|

| R, S, T | AC input 200–230 V |

| U, V, W | Motor connections |

| L1, L2 | Control power supply |

| B1, B2, B3 | Braking resistor / bridge (B2–B3) |

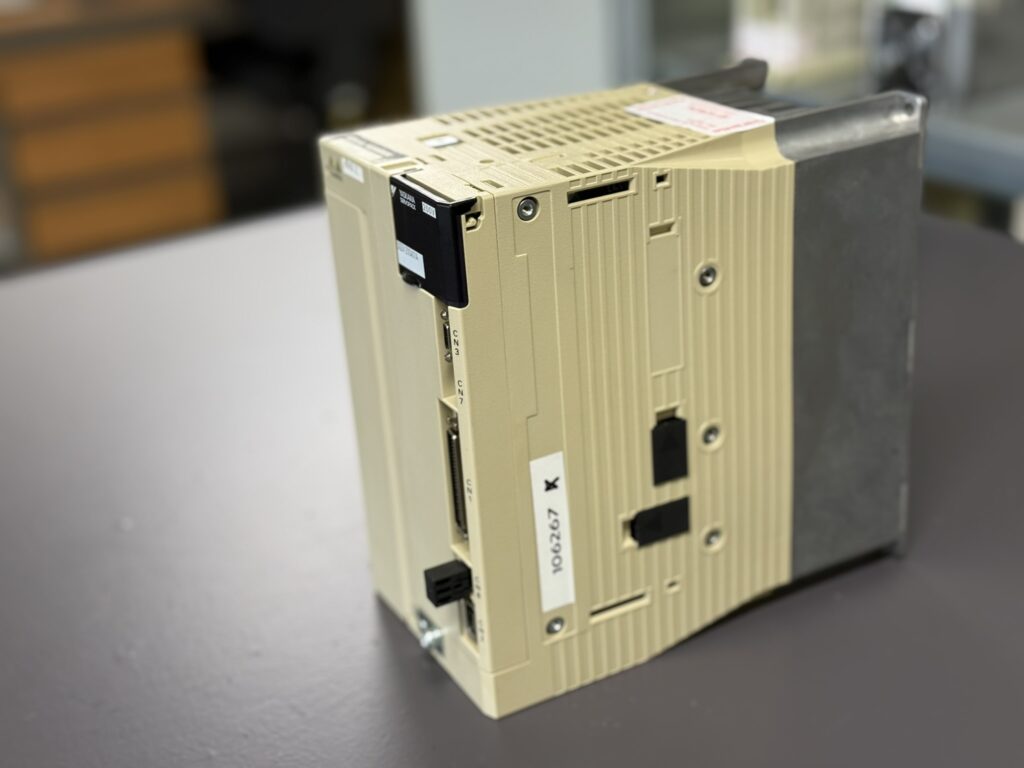

| CN1 | Controller / PLC interface |

| CN2 | Encoder connector |

| CN8 | External fan supply (depending on model) |

| FG | Protective earth |

Internal Assemblies

| Assembly | Designation | Description |

|---|

| Control board | SGDV-IFA01B / 400-002-080-B0Z | Main logic, parameter management, communication |

| Power supply board | SGDV-CB200AAA / 400-003-486-B0Z Rev.B | Control power generation |

| Capacitor board | SGDV-CC200AAA / 400-003-485-A0Z Rev.A0 | DC bus smoothing stage |

| Power stage | Power module | IGBT output stage for motor current |

| Fan | Built-in fan | Cooling for power stage |

| Thermal sensors | Temperature monitoring | Heat-sink and internal temperature sensors |

Error and Alarm Table (Main Alarms)

| Code | Description | Meaning | Solution |

|---|

| A.7AB | Fan stopped | Internal fan not running | Replace fan, clean cooling channel |

| A.7A0 | Heat-sink overtemperature | >100 °C detected | Improve cooling, fix airflow issues |

| A.100 | Overcurrent / IGBT overheating | Power stage overloaded | Check power module, motor wiring |

| A.300 | Regeneration error | Brake resistor issue | Check resistor / bridge |

| A.320 | Regenerative overload | Excess return energy | Increase resistor capacity |

| A.400 | Overvoltage | DC bus too high | Check mains supply |

| A.410 | Undervoltage | Supply too low | Stabilize input |

| A.510 | Overspeed | Motor speed too high | Check parameters |

| A.C90 | Encoder communication error | No encoder data | Check cable / encoder |

| A.830 | Battery alarm | Low absolute encoder battery | Replace battery |

Typical Applications

| Machine / Area | Application |

|---|

| CNC milling machines | X/Y/Z axes |

| Lathes | Tailstock, tool changer |

| Handling units | Pick-and-place axes |

| Assembly automation | Precision linear axes |

| Packaging machinery | Positioning axes |

Service Notes

| Topic | Recommendation |

|---|

| Fan replacement | Every 3–5 years or when noisy/weak |

| Temperature monitoring | Check airflow regularly |

| Cleaning | Remove dust from cooling channels |

| Parameter backup | Backup before servicing |

| Motor current test | Mandatory after power stage repair |

| Test run | Several load cycles recommended |