27.04.2025 by Viktor Siebert

Interesting Case: Yaskawa Servo Motor SGMGH-30ACA61 Filled with Oil/Emulsion

Problem Description

A Yaskawa servo motor type SGMGH-30ACA61 arrived at our facility with an unusual issue: it was completely filled with oil and emulsion. The customer had previously purchased a replacement motor from their supplier, which operated for approximately two months before the servo pack (Yaskawa SGDH-30AE) reported an overload error.

Our Expertise

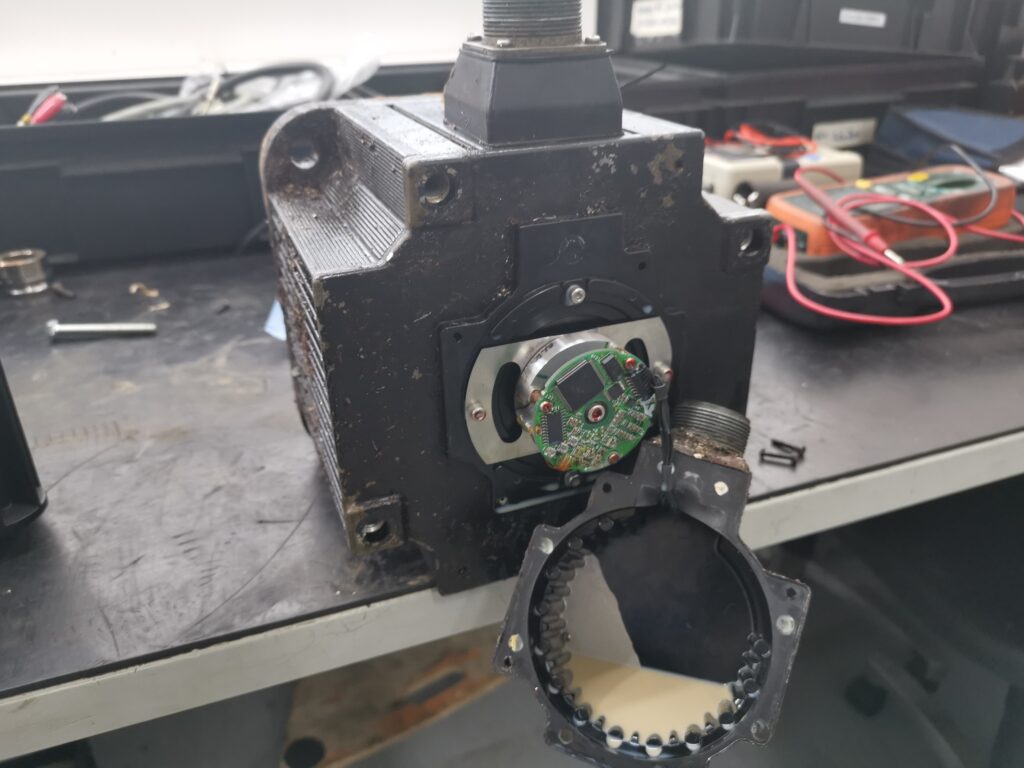

After removal, the customer brought the motor to us for inspection. We were surprised to find oil and emulsion inside the motor when we opened it (see image). When asked, the customer explained that he had installed the motor in an environment where emulsions flow like a river. He previously used a similar motor designated SGMGH-30ACA6S—note the “S” at the end.

Cause of the Problem

The customer’s supplier, who claimed expertise, incorrectly assured him that the “1” at the end of the type designation was insignificant. In reality, this was a critical error: the letter “S” indicates an “Oil Seal,” a special seal designed to prevent liquid ingress.

Critical View on Dealer Practices

When the customer confronted the Italian supplier about being sold the incorrect motor, the supplier immediately distanced himself and stopped responding to emails and phone calls. Unfortunately, such practices are increasingly common. Many dealers attempt to resell industrial products without sufficient technical knowledge, often sourced cheaply from China with significant profit margins. Frequently, these products are cosmetically refurbished and falsely sold as “new.”

Our Findings and Solution

The customer also complained about the high cost—nearly 3,000 euros for a motor delivered in new packaging. Our standard inspection revealed that the motor was neither new nor properly refurbished. The bearings showed at least 10 years of usage.

Restoration Measures

Subsequently, we were commissioned to professionally refurbish the motor. Unfortunately, the encoder had already been destroyed due to liquid penetration. We thoroughly cleaned the motor, dried it in a specialized oven to normalize electrical resistance values, installed a suitable oil seal, and replaced the encoder and ball bearings. Finally, the motor was repainted and extensively tested on our testing facility.

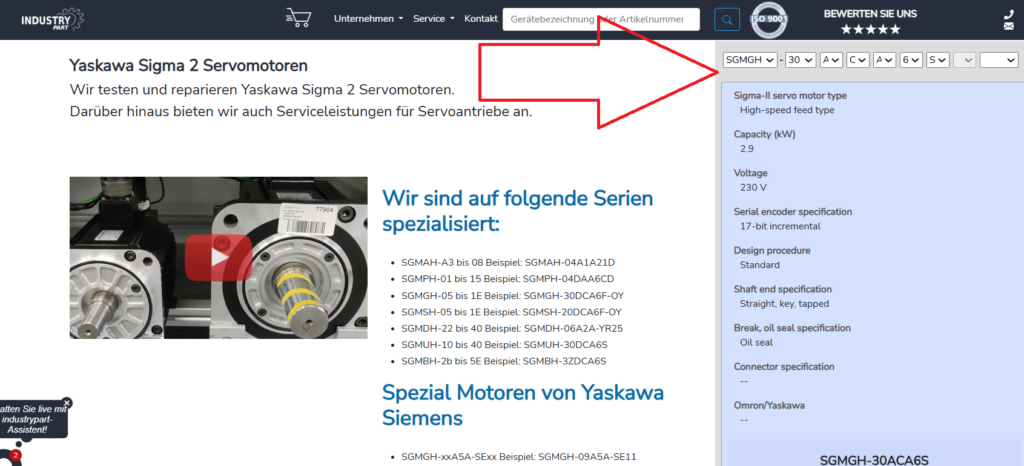

Our Recommendations to the Customer

We thoroughly advised the customer on future considerations. Additionally, we developed specialized software—a “Configurator”—that accurately decodes type designations, clearly identifying the installed components (see image or click the link).

Should uncertainties arise, we offer non-binding advice and gladly provide necessary information free of charge.

Warning and Appeal

Finally, we appeal to all customers: Carefully vet your suppliers and, if necessary, verify product authenticity. This helps prevent issues and supports the fight against counterfeit products that increasingly flood the European market.

Further Information

Sigma-II servo motor type: High-speed feed type

Capacity (kW): 2.9

Voltage

230 V

Serial encoder specification

17-bit incremental

Design procedure: Standard

Shaft end specification: Straight, key, tapped

Break, oil seal specification: Oil seal

Information about the mentioned Servopack and Servomotor:

More information about our Yaskawa repairs can be found here.

📞 Feel free to contact us if you have any questions regarding your Yaskawa drive technology. Our experienced team is always ready to assist you.