06.11.2025 by Viktor Siebert

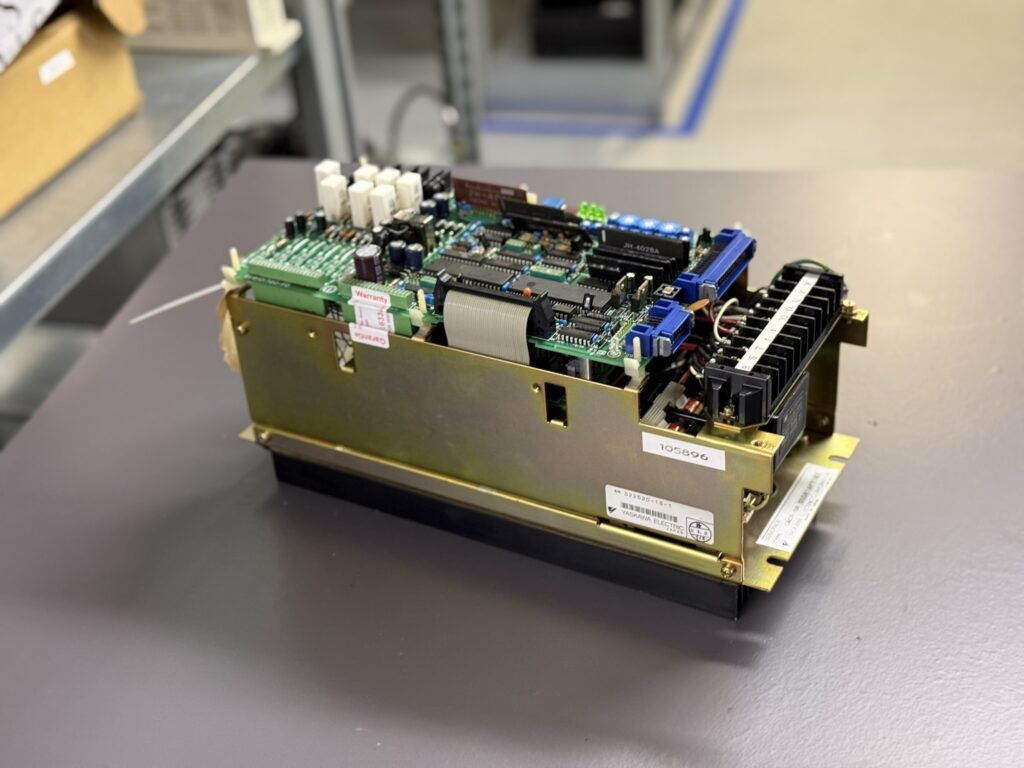

Repair of a Yaskawa CACR-SR05SB1AFY187 Servopack tested with USAFED-05FS1S Servomotor

Initial Condition and Diagnosis.

The Yaskawa CACR-SR05SB1AFY187 arrived with Alarm 1 Overcurrent immediately after power-up.

According to Yaskawa’s diagnostic table, this alarm indicates that an overcurrent was detected in the main circuit, typically caused by a defective transistor, overload at the output, or a motor ground fault.

Since the alarm appeared instantly and the fuses were intact, the issue clearly originated inside the power section.

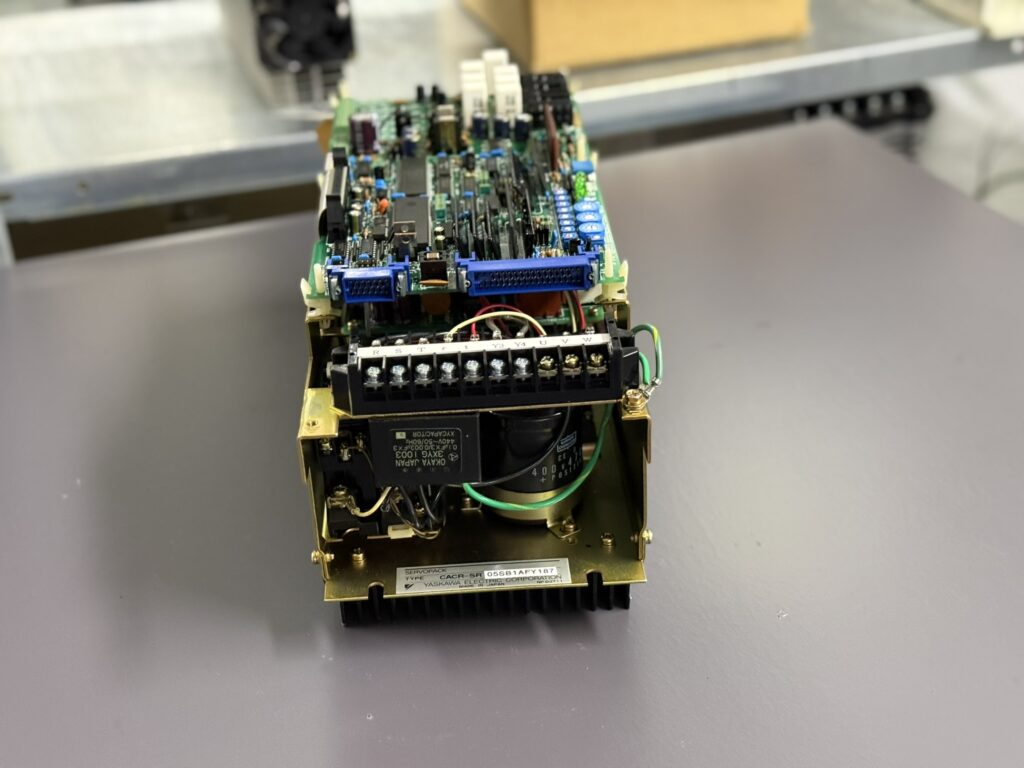

Upon disassembly, visual inspection revealed heat discoloration on the power transistors and surrounding copper traces. The lower section of the power board showed localized darkening near the IGBT modules. Insulation testing between motor phases (U, V, W) and the DC bus returned readings in the kilo-ohm range a clear sign of internal leakage or short circuit.

Repair and Restoration

The power stage was completely disassembled and cleaned. Each transistor module was tested under controlled voltage. Two modules exhibited a shorted collector-emitter path. These were replaced together with the parallel free-wheeling diodes.

The gate drivers and snubber networks were checked for stability and switching symmetry. The control PCB was thoroughly cleaned with isopropanol and inspected under magnification to ensure no flux or conductive residue remained. Aging electrolytic capacitors in the DC bus were replaced preventively. The connectors to the motor and encoder were renewed to eliminate potential contact resistance.

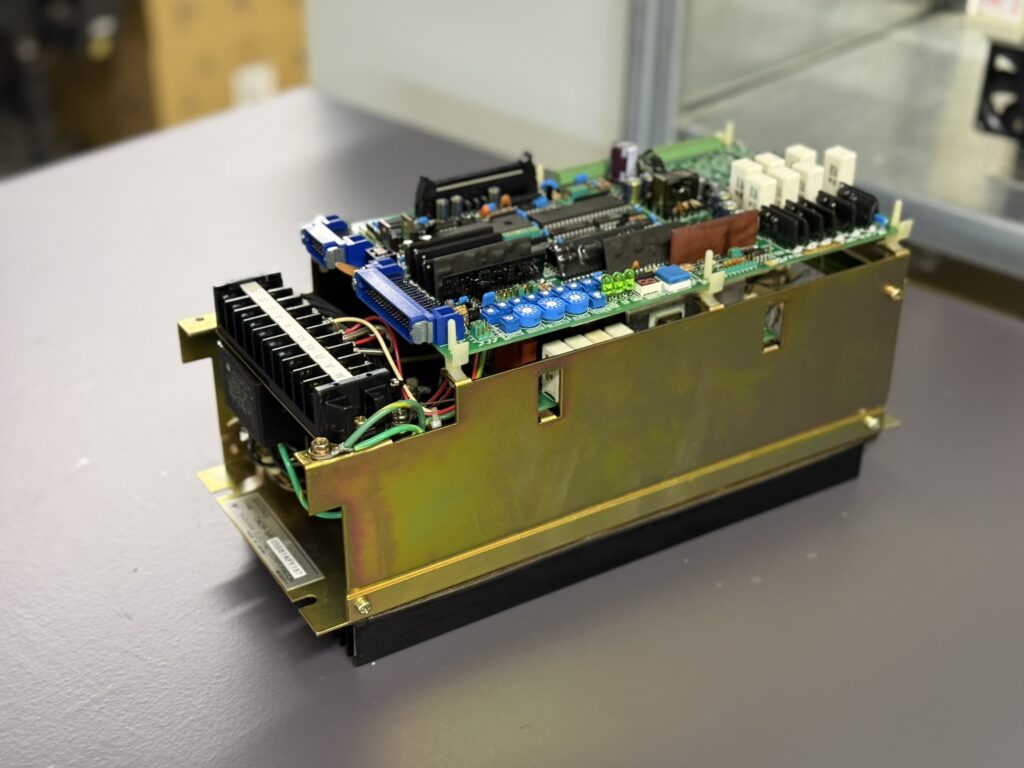

All components were reassembled using new thermal compound and re-aligned to ensure optimal cooling. Insulation and functionality tests were performed prior to power application.

Testing and Verification

The repaired Servopack was tested with a Yaskawa USAFED-05FS1S motor on our in-house test bench. The initial startup completed successfully, with stable DC bus voltage and balanced output current. The unit ran smoothly at no load and responded correctly to speed commands.

During the load phase, several acceleration and deceleration cycles were performed. All protection features (overcurrent, overvoltage, overload) responded within specification.

Long-term thermal testing followed, with 50% and 80% load for six hours. The heatsink temperature remained stable below 45 °C. The current waveform was symmetrical and noise-free. The original fault Alarm 1 (Overcurrent) did not reappear.

Preventive Measures

Because overcurrent alarms often result from aged semiconductors or capacitor degradation, the following preventive steps are recommended:

- Regular insulation checks between motor cables and ground

- Periodic DC bus capacitor inspection every 5 years

- Ensure sufficient cooling and airflow

- Avoid rapid power cycling without capacitor discharge delay

Conclusion

The Yaskawa CACR-SR05SB1AFY187 has been fully restored, tested, and verified.

The root cause of Alarm 1 (Overcurrent) was an internal transistor short. After replacement of the defective modules, recalibration, and thermal reconditioning, the unit operates within all Yaskawa specifications and is ready for continuous use.

Result:

Fault cleared, all protection circuits operational, power modules renewed, and long-term load testing successfully completed.

To mentioned Yaskawa Drive: Yaskawa CACR-SR05SB1AFY187 Servopack

Servo Motor mentioted: Yaskawa USAFED-05FS1S AC Servo Motor

More details about our Yaskawa repair services can be found here:

Yaskawa drive Repair by Industrypart

📞 Feel free to contact us with any questions about your Yaskawa drive technology.

Our expert team is happy to help!

Technical Specifications:

| Specification | Value | Note |

|---|

| Manufacturer | Yaskawa Electric | Japan |

| Series | CACR-SR | AC Servopack D-Series |

| Model | CACR-SR05SB1AFY187 | Servo amplifier for 0.5 kW motor |

| Rated voltage | 3-phase 200–230 V AC ±10 % | 50/60 Hz |

| Control circuit | Single-phase 200–230 V AC | 50/60 Hz |

| Output current (rated) | 3.5 A | Continuous |

| Maximum current | 10.6 A | Short-term |

| Control method | PWM transistor control | With optical encoder |

| Feedback | Incremental encoder 6000 P/R | Combined with USADED-05E motor |

| Protective functions | Overcurrent, overvoltage, undervoltage, overload, overheating, regeneration and CPU error | LED indication |

| Environment | 0–40 °C, 20–80 % RH (non-condensing) | |

| Weight | Approx. 5.5 kg | Basic unit |

Typical Alarm Codes of CACR-SR Series

| LED Code | Detection | Meaning / Cause | Corrective Action |

|---|

| 1 – Overcurrent | Overcurrent in main circuit | Short circuit, defective transistor module, or motor ground fault | Check motor and replace Servopack |

| 2 – Circuit Protector Tripped | Line protection triggered | Thyristor or fuse failure | Restart after inspection or replace Servopack |

| 3 – Regenerative Trouble | Regeneration circuit error | Defective transistor or open resistor (SR60 type) | Check regeneration path |

| 4 – Overvoltage | DC bus voltage too high | Excessive inertia or regeneration failure | Inspect mechanical load |

| 5 – Overspeed | Motor speed too high | Encoder or wiring error | Check phase wiring |

| 6 – Voltage Drop | Undervoltage | Mains or diode failure | Inspect power source |

| 7 – Overload | Load too high | Continuous load >105 % rated | Reduce mechanical load |

| 8 – Heatsink Overheat | Heatsink overheating | Fan failure or ambient temp >55 °C | Check cooling system |