20.05.2025 by Viktor Siebert

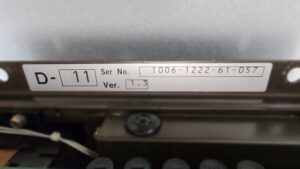

Repair of an Okuma VACIII D11 (1006-1222)Spindle Drive – Troubleshooting and Preventive Measures

Repair of an Okuma VACIII Spindle Drive – Troubleshooting and Preventive Measures

Repairing Okuma VACIII drive units, especially the D11 or 1006-1222 models, is one of our specialties. Recently, we received a particularly interesting unit for repair that displayed the common error “Alarm 17 – UVP, Power circuit low voltage.”

The Problem – Intermittent and Tricky

Interestingly, the issue was not consistently present. Initially, the machine ran flawlessly for weeks, but then the fault would appear suddenly and without any apparent reason, unaffected by time of day or temperature conditions. After a brief problematic period, the unit would again run smoothly, as if nothing had happened. This scenario persisted for two years.

The customer faced a difficult decision: replacing the unit with an OEM part would have cost over 10,000 euros—economically hardly justifiable. As the fault began to appear more frequently, eventually several times daily, the customer sought an alternative solution and found our services.

Our Solution – Comprehensive Preventive Overhaul

We are very familiar with this particular error, as it is one of the most common faults in Okuma VACIII drives. For this, we have developed a special flat-rate repair service that goes far beyond just rectifying the immediate issue, aiming instead at comprehensive prevention of future defects.

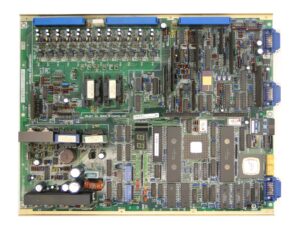

During our repair process, we replace more than 30 critical components, including:

- Electrolytic capacitors

- Buffer capacitors

- Measuring resistors

- Optoelectronic components

- Current and voltage measurement modules

- Transistors

- Relays

- Fans

Additionally, each unit undergoes a thorough cleaning and drying process in a specialized drying oven. This ensures not only that the immediate problem is resolved but also significantly reduces the risk of future failures.

Extensive Testing Under Real Conditions

After the repair, each drive undergoes extensive testing directly in an original Okuma machine under realistic operating conditions. These tests guarantee that the unit is fully operational and reliable for many years to come.

Customer Satisfaction and Sustainable Solutions

After approximately five working days, our customer received the refurbished drive. Since then, it has operated flawlessly. Impressed by the result, he decided to proactively refurbish additional units from his machinery, specifically Axis Modules. He is convinced that preventive maintenance significantly contributes to the long-term safety and operational reliability of his equipment.

Preventive Repair – The Smart Choice

Our experience shows that timely and preventive maintenance not only minimizes downtime in the short term but also significantly reduces long-term costs. Our customers benefit from reliable machines, prolonged component life, and predictable machine availability.

Don’t wait until it’s too late—choose preventive measures early to secure your production processes in the long term!

Price and Delivery Time for Okuma VACIII D11 (1006-1222) Spindle Drive

For more information about our Okuma repairs, please click here.

📞 Feel free to contact us if you have any questions regarding your Mitsubishi drive technology. Our experienced team is always ready to provide you with expert advice and support.

Alarm Messages and Troubleshooting

| Alarm | Description |

|---|

| 08 | Communication Error |

| 10 | Motor Cable Overcurrent |

| 11 | Inverter Bridge Short |

| 12 | Regenerator IGBT Short |

| 14 | Input Voltage Drop |

| 15 | Open Phase |

| 16 | Loss of Arithmetic Circuit Power (+5V too low) |

| 17 | UVP, Power Circuit Low Voltage |

| 18 | Interval Loop Error |

| 19 | Motor Overload |

| 20 | Heat Sink Overheat |

| 21 | Data Setting Abnormal |

| 30 | Excessive Velocity Deviation Error |

| 34 | Occurs in both VACII and VACIII units |

| 37 | PG Feedback Error |

| FF | RAM Error |