05.11.2025 by Viktor Siebert

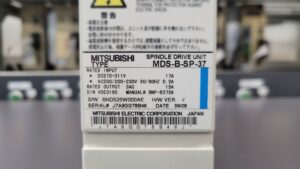

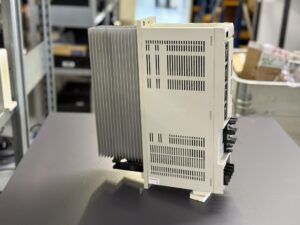

Repair of a Mitsubishi MDS-B-SP-75 Spindle Drive Unit

Initial Condition and Analysis

The Mitsubishi MDS-B-SP-75 Spindle Drive Unit arrived with the display showing alarm “n” or “1”, indicating an internal power module error. These error codes typically occur when an asymmetrical load or a shorted gate path exists within the IGBT module (Insulated Gate Bipolar Transistor). For the customer, the symptom appeared as a sudden spindle stop after a short operating time a typical sign of a damaged output stage.

During the first inspection phase, the device was completely cleaned and connected to the test bench. Already at power-on, the drive showed irregular current consumption. The DC bus voltage was built up correctly, but the unit switched off immediately during the start attempt. This behavior pointed to an internal short circuit or a defective feedback circuit in the power stage.

Diagnosis and Cause Analysis

Measurements on the gate signals and DC bus voltages revealed irregularities indicating a partially defective IGBT module. The fault was not visible from the outside, as the module showed no burn marks. Only after removing the power assembly and performing thermal testing did it become clear that one section of the module did not conduct properly and caused intermittent overcurrent spikes.

At the same time, the control board (RK311B) showed visible stress marks in the transistor drive section. Several components displayed thermal aging, which resulted in distorted signal paths. This was a classic secondary failure caused by the defective power path itself.

Repair Process

The faulty power assembly was completely removed and replaced with a verified spare module. A preventive overhaul was then carried out on the entire power board RK122B-SP-75, including the replacement of high-frequency driver stages, gate capacitors, and current sensors.

The control board was also refurbished: the affected signal paths and timing circuits were checked, solder joints were renewed, and aged components were replaced. The board was cleaned in an ultrasonic bath and then thermally treated to remove residual moisture.

Functional Testing and Quality Control

After mechanical and electrical restoration, the unit was tested on the Mitsubishi spindle test bench under rated load. A spindle motor simulation with various speed profiles was carried out. The amplifier achieved full performance with stable temperature behavior. Insulation and leakage tests produced perfect results, and DC bus balancing was confirmed.

To ensure reliability, extended burn-in tests were performed over several hours under variable load conditions. The drive remained fully stable, communication with the control system was uninterrupted, and no new alarms occurred.

Preventive Measures and Recommendations

Due to the unit’s age of over 20 years, all electrolytic capacitors in the control and power sections were replaced as a preventive measure. The cooling fans were inspected and replaced if necessary to ensure sufficient airflow for the IGBT module.

It is strongly recommended to perform maintenance every 3–5 years, including checks of the DC bus voltage, gate signals, and fan condition. Failure of the power section can damage not only the spindle drive but also neighboring modules in the DC bus.

Final Result

After all tests were completed, the device was documented, labeled, and released for shipment. The MDS-B-SP-75 operated stably under load, and all functional parameters met the manufacturer’s specifications.

This repair clearly demonstrates the importance of precise diagnostics and preventive replacement of aging components, especially in older Mitsubishi drive systems that continue to operate reliably in CNC machines around the world.

To mentioned Mitsubishi Drive: Mitsubishi MDS-B-SP-75 Spindle Drive Unit

More details about our Mitsubishi repair services can be found here:

Mitsubishi drive Repair by Industrypart

📞 Feel free to contact us with any questions about your Mitsubishi drive technology.

Our expert team is happy to help!

Technical Specifications

| Specification | Value | Remark |

|---|

| Manufacturer | Mitsubishi Electric Corporation | Japan |

| Device Type | Spindle Drive Unit | Part of the MDS-B system |

| Series | MDS-B-SP | Spindle amplifier with external power supply (e.g. MDS-B-CV or MDS-B-CVE) |

| Input Voltage (DC) | 270–311 V | From the converter DC bus |

| Input Voltage (AC) | 200–230 V AC, 50/60 Hz | For control power |

| Input Current | 17 A DC / 0.2 A AC | According to nameplate |

| Output | 3 AC, 15 A | For spindle motor power |

| Power | 7.5 kW | Rated output |

| Weight | approx. 8 – 10 kg | Depending on revision |

| Compatible Motors | Mitsubishi SJ Series | 5.5 – 7.5 kW spindle motors |

| Manufacturing Date | 1999/08 | Serial J7A9GG78B46 J |

| Manual Reference | BNP-B3759 | MDS-B/SP Service Manual |

Components

| Type | Board Designation | Quantity |

|---|

| Control Board | RK311A / RK311B (BN634A769G51 C / BN634A817G51 A) | 1 |

| Power Board | RK122D-SP-75 BN638A919G51 Ж / RK122B-SP-75 BN634A813G51 | 1 |

| Power Section | Power unit (IGBT module + heatsink assembly) | 1 |

Alarms & Faults (Extract from “Alarm list Spindle MDS_A_SP MDS_B_SP Mitsubishi”)

| Alarm No. | Name | Description | Operation |

|---|

| 31 PSO | Power Module Overcurrent | Overcurrent detected in IPM of spindle drive | PR |

| 35 DE | Data Error | Excessive position command from NC | PR |

| 40 KE1 | TK Unit Change Error | Error in TK unit switching procedure | PR |

| 41 KE2 | TK Unit Communication Error | TK unit communication failed | PR |

| 44 CAXE | C-Axis Changeover Alarm | Axis switching error during C-axis operation | NR |

| 46 OHM | Motor Overheat | Motor or cooling blower overload detected | NR |

| 50 OL | Overload | Motor current exceeded limit for a fixed duration | NR |

| 52 OD | Excessive Error | Position deviation exceeded limit | NR |

| 82 NSP | Power Supply No Signal | Break or incorrect power supply connection | PR |

| E7 NCE | NC Emergency Stop | Emergency stop signal received from CNC | PR |