07.10.2025 by Viktor Siebert

Repair of an Overheated Mitsubishi MDS-B-SP-300 Spindle Drive with Complete Power Stage Failure

Repair Story.

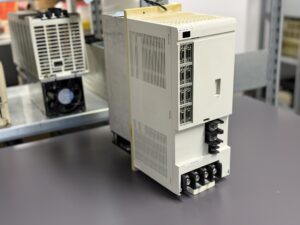

This MDS-B-SP-300 spindle drive arrived from a major automotive supplier in Poland, who was facing a full production stop on a Mazak turning center.

The replacement module was obsolete, unavailable from the OEM, and the quoted exchange price exceeded any reasonable budget.

Downtime was critical, each hour of delay meant lost production.

Upon inspection, the drive showed no power-on indication, no relay clicks, and was completely dead.

After opening, we found heavy contamination from oil mist, dust, and metallic debris. The cooling fan had seized, creating a dangerous heat buildup.

Our diagnostics revealed that the IGBT power module had failed due to thermal overload, damaging the internal power supply section and multiple gate driver ICs.

The repair required complete disassembly down to PCB level.

The drive was cleaned using an ultrasonic bath, followed by oven drying at 60 °C. Damaged components were replaced, including the transistor module, gate drivers, diodes, and regulators.

We reworked solder joints on the RK311B control board and verified firmware consistency.

All electrolytic capacitors and the fan unit were replaced preventively.

Testing took place on our Mitsubishi spindle test bench, using an MDS-B-CVE power supply and a 30 kW SJ-V-30 motor under CNC simulation.

The drive successfully ran through 8 hours of thermal and overload testing up to 6000 rpm without any deviation.

After 48 hours turnaround, the customer had the machine back online within 3 days, at only a quarter of the OEM replacement cost.

This repair demonstrates the critical importance of preventive fan and contamination maintenance, a small failure that can escalate into a full system shutdown if neglected.

Preventive Maintenance Recommendations

- Replace cooling fans every 2 years or 8,000 h runtime

- Clean dust and oil deposits with antistatic air

- Inspect connectors CN1/CN2 for oxidation

- Perform insulation test between power and chassis

- Measure capacitor ESR after 5 years

- Check heatsink temperature under full load

Proper maintenance ensures reliability, reduces costs, and prevents unexpected downtime.

Conclusion

The Mitsubishi MDS-B-SP-300 remains a robust spindle drive, known for its durability and precise control.

With professional servicing and preventive maintenance, it continues to perform reliably even decades after production ended.

To mentioned Mitsubishi Drive: Mitsubishi MDS-B-SP-300 Spindle Drive

More details about our Mitsubishi repair services can be found here:

Mitsubishi drive Repair by Industrypart

📞 Feel free to contact us with any questions about your Mitsubishi drive technology.

Our expert team is happy to help!

Technical Specifications

| Specification | Value |

|---|

| Manufacturer | Mitsubishi Electric Corporation, Japan |

| Model | MDS-B-SP-300 |

| Device Type | Spindle Drive Unit |

| Series / Class | MDS-B, 200 V Class |

| Input (DC) | DC 270–311 V, 144 A |

| Input (AC) | AC 200/200–230 V, 50/60 Hz, 0.2 A |

| Output | 3-phase AC, 130 A |

| Power Rating | 30 kW |

| Standard | DIN VDE0160 |

| Cooling | Forced air cooling with integrated fan |

| Weight | approx. 14 kg |

| Dimensions (W × H × D) | approx. 250 × 380 × 200 mm |

| Software Version (S/W) | BND525W000AAK |

| Hardware Version (H/W) | D |

| Serial Number | J7A9QG4ZK1T |

| Production Date | 1996/12 |

| Manual Reference | BNP-B3890 |

| Certification | CE, TÜV Rheinland Approved |

Operating Environment & Compatible Equipment

The MDS-B-SP-300 spindle amplifier belongs to the 200 V class Mitsubishi MDS-B series.

It is typically used in Mazak turning centers, DMG Mori machining centers, and CNC milling machines equipped with Mitsubishi Meldas 500/600/60 series controls.

It provides stable spindle control for high-speed and precision machining applications.

Compatible systems include MDS-B-CVE power supply modules and MDS-B-V1/V2 servo drives.

Matching spindle motors include models such as SJ-V-30, SJ-VL5.5, and SJ-11XW8Z.

Functional Description

The MDS-B-SP-300 performs precise spindle motor control, managing speed, torque, and acceleration through a vector control loop.

It receives feedback from the spindle encoder and command signals from the CNC controller.

Key internal sections:

- Control Board (RK311B or BN634A817G51A): Handles regulation, communication, and diagnostics.

- Power Board (RK125B-SP-300 or BN638A021G51A): Manages current flow, IGBT control, and power protection.

- Power Module (IPM): Converts DC bus voltage into three-phase output for the spindle motor.

Safety and protection features include:

- Current and voltage monitoring

- Temperature and overload protection

- CRC and encoder signal checks

- Emergency stop logic and fan monitoring

Communication with the CNC system is via CN1 (control interface) and CN2 (encoder input).

Alarms & Troubleshooting

| Code | Description | Cause | Remedy |

|---|

| 12 ME1 | Memory error 1 | ROM/RAM checksum failure | Replace or reprogram control PCB |

| 13 SWE | Software process error | Process timeout | Reset and reload firmware |

| 17 ADE | AD converter error | Fault during initialization | Check analog detection circuit |

| 21 NS2 | No spindle encoder signal | Encoder signal missing | Inspect encoder wiring and connection |

| 23 OSE | Speed deviation | Motor overshoot sustained | Check load and speed parameters |

| 31 OS | Overspeed | Speed exceeded 115% of max | Verify encoder feedback |

| 32 PMOC | Power module overcurrent | Overcurrent in IPM | Replace transistor module |

| 34 DP | CRC error | Data corruption in NC link | Reconnect and check interface cable |

| 36 TE | Transmission error | CNC ↔ Drive link interrupted | Clean connector, test continuity |

| 46 OHM | Motor overheat | Thermal limit exceeded | Replace fan, inspect thermal sensor |

| 50 OL | Overload | Excessive current draw | Check bearings and lubrication |

| 82 NSP | Power supply no signal | Missing input voltage | Verify supply and fuses |

| E1 WOL | Overload warning | 80% overload threshold reached | Clean and inspect cooling system |

| E7 NCE | NC emergency stop | Stop command from CNC | Check CNC signal input |

Components

| Assembly | Reference / Code | Function | Test / Repair Notes |

|---|

| Control Board | RK311B or BN634A817G51A | CNC interface, logic control | Visual inspection, capacitor test |

| Power Board | RK125B-SP-300 or BN638A021G51A | Power conversion and drive | Isolation and transistor test |

| Power Module (IPM) | Main power module | Converts DC to AC | Load test under temperature monitoring |

| Fan Unit | 24 V DC | Cools power electronics | Replace every 2 years |

| Power Supply Section | Integrated | Logic and driver supply | Verify output voltages |

| Encoder Interface | CN2 | Motor feedback | Check signal level and shielding |