15.06.2025 by Viktor Siebert

Repair of Mitsubishi HF-H104BS AC Servo Motor

The Challenge

Several weeks ago, we received a Mitsubishi AC servo motor, type HF-H104BS, for repair. While we had already repaired many motors in this series, this particular one included a holding brake—something we hadn’t standardized before. The customer was unsure whether the motor was repairable at all, let alone whether quality spare parts were still available. Mitsubishi does not offer repairs and the model is being discontinued, which makes replacements expensive.

The Price-Performance Dilemma

Discontinued parts quickly become expensive, and many customers ask themselves: is a new purchase worth it? The rule of thumb says that a repair should not exceed 30% of the new purchase cost—if the technology is still actively supported. But when manufacturers discontinue support, prices rise. Are we jumping on that bandwagon too? No. We at Industrypart believe in fairness: optimized processes and access to spare parts enable affordable, sustainable repairs.

Our Approach

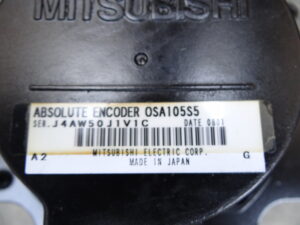

A first inspection revealed: both the brake (SBR-110-057) and the encoder (OSA105S5) needed attention. Thanks to our in-house test bench, we simulated real-world conditions and identified weak points quickly. Our repair process included:

- Replacement of bearings and seals

- Full cleaning, paint removal, and repainting

- Final load test under real stress conditions

Result

After repair, the motor ran for over 6 hours under full load without issue. The customer was satisfied, and so were we.

To mentioned Mitsubishi Motor: Mitsubishi HF-H104BS AC Servomotor

More details about our Mitsubishi repair services can be found here:

Mitsubishi motor Repair by Industrypart

📞 Feel free to contact us with any questions about your Mitsubishi drive technology.

Our expert team is happy to help!

Technical Specifications (HF-H104BS)

| Parameter | Value |

|---|

| Voltage/ Current | 3AC 348 V 2,0 A |

| Ingress Protection | IP67 |

| Power Output | 1.0 kW |

| Rated Speed | 3000 rpm |

| Weight | ~8.6 kg |

| Brake | Yes (SBR-110-057) |

| Encoder | OSA105S5 (absolute) |

Application Environment

Typically used in CNC machining centers, often paired with MDS-DH-V1-10 or V2 series MELDAS drives.

Functional Description

This medium-inertia AC servo motor with integrated holding brake is ideal for vertical axes where position holding during power loss is crucial. It features a high-resolution absolute encoder (1.000,000 pulses/rev).

Alarms and Troubleshooting

| Alarm Code | Description | Possible Cause | Solution |

|---|

| 50 | Overload protection triggered | Prolonged overload | Check load, run diagnostics |

| 51 | Max current exceeded | Blockage, short circuit | Inspect mechanics and cables |

| A.10 | Overcurrent | IGBT or cable fault | Check insulation, test motor |

| A.32 | Overheat (motor or brake) | Blocked ventilation, brake fault | Clean fan, replace brake |