30.04.2025 by Viktor Siebert

Spindle Motor Failure with a Bang – Causes and Successful Repair

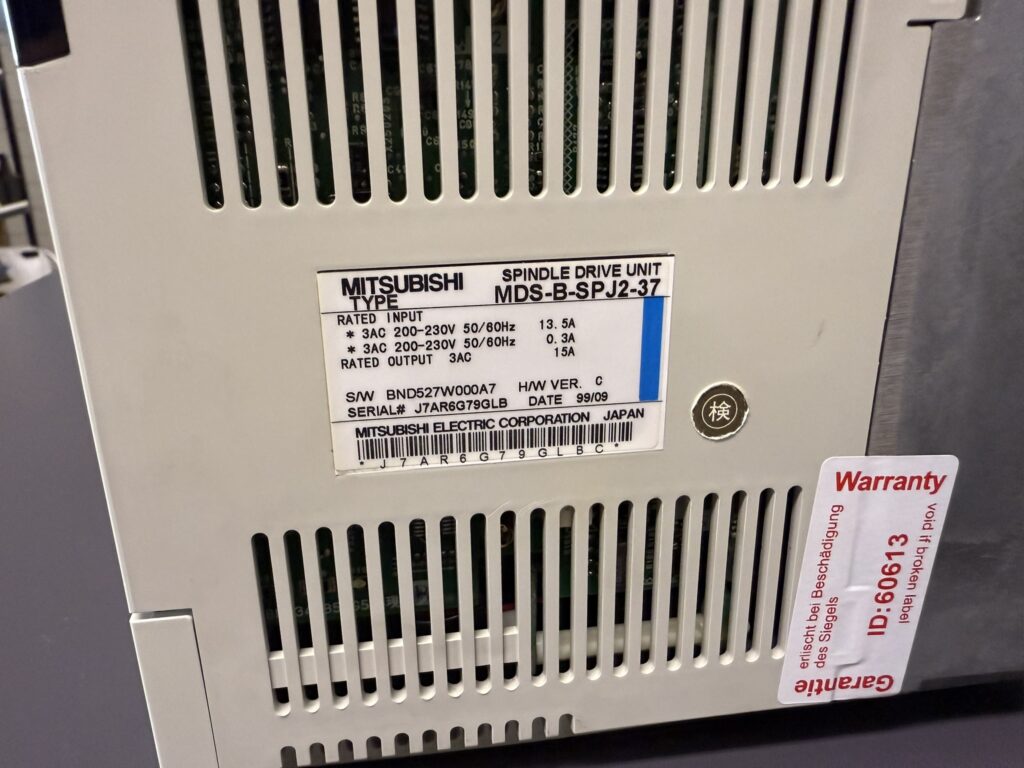

The incident at the customer spindle drive MDS-B-SPJ2-37 with bang and smoke

At one of our customers’ facilities, the spindle motor SJ-P3.7A experienced repeated failures. Eventually, the associated spindle drive MDS-B-SPJ2-37 from Mitsubishi also failed – accompanied by a loud bang.

One of the customer’s employees reported a loud explosion, followed by a dense cloud of smoke rising from the machine’s electrical cabinet. He was seriously concerned and feared that the machine was on fire.

The Cause of the Bang

Fortunately, it turned out that “only” the buffer capacitor inside the spindle drive had blown. This capacitor’s role is to stabilize and smooth the internal voltage level.

Later investigations revealed that the spindle motor suffered from a winding short circuit, caused by long-term emulsion accumulation, which had degraded the insulation inside the motor.

Typical Symptoms Before Failure

Due to the developing short circuit, the motor would sometimes run for hours without any issues, then suddenly trigger sporadic fault messages.

Initially, these faults could be “cleared” by simply restarting the machine. However, over time the electrical stress became too much for the spindle drive to handle – ultimately resulting in the bang.

A Stroke of Luck

Fortunately, only the capacitor was destroyed. Although the inside of the unit was completely covered in leaked electrolyte, the rest of the electronics remained largely intact.

There was no fire damage, and the spindle drive could be successfully restored.

Our Measures

We thoroughly overhauled the spindle drive:

- Complete cleaning of all components with special cleaning agents

- Preventive overhaul of the PCBs

- Test runs with compatible CNC control and a new motor

After these steps, the drive was fully operational again.

Customer’s Focus on Sustainability

The customer was, of course, informed about the defective motor. Luckily, he had an identical new motor in stock, which he immediately installed.

However, he also plans to have the damaged motor refurbished, as sustainability and cost-effectiveness are important to him.

Our Insight

With this case study, we would like to show:

Machine failures are often not caused by a single faulty component, but by a chain of contributing factors.

It is always worth investigating the true root cause – to sustainably fix the issue and prevent future problems.

Technical Specifications

- Model: MDS-B-SPJ2-37

- Rated Output: 3.7 kW

- Input Voltage: Three-phase 200–230 V, 50/60 Hz

- Input Current: 13.5 A (power board), 0.3 A (control board)

- Output Current: 15 A

- Compatible Spindle Motors: Mitsubishi SJ-P3.7A, SJ-P2.2

- Speed Range: 0–12,000 rpm

- Torque: 10.8 Nm

- Dimensions: Approx. 200 mm x 150 mm x 100 mm

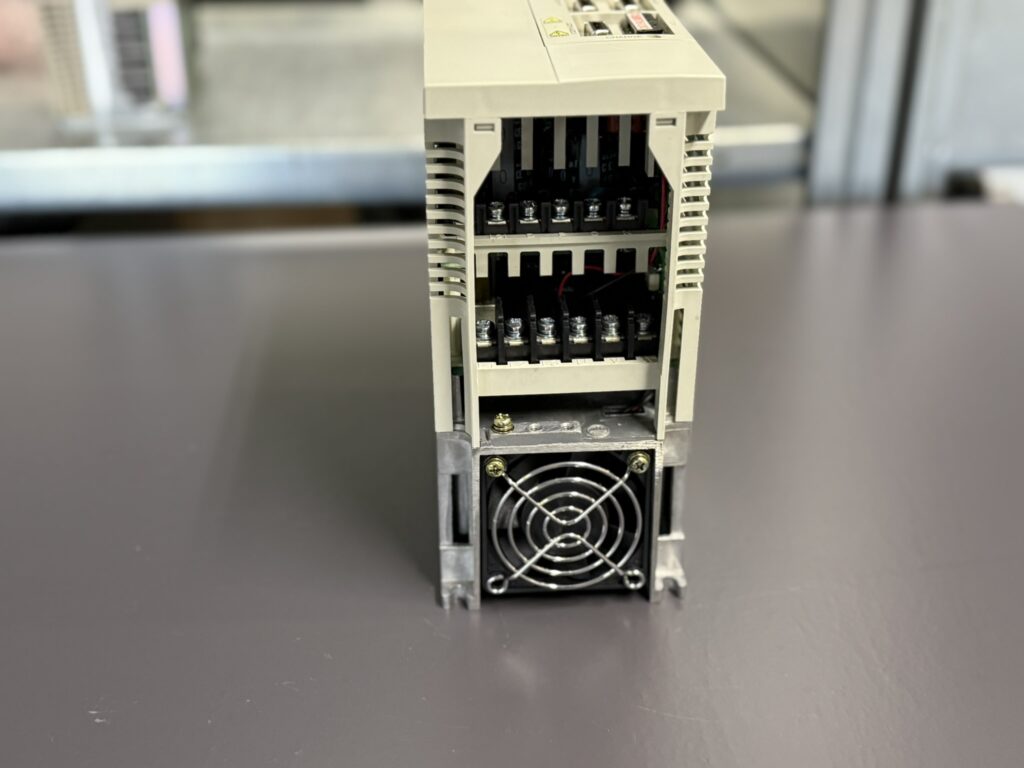

- Cooling: Air-cooled; requires sufficient ventilation inside the control cabinet

- Interfaces: Compatible with Mitsubishi MELDAS series CNC controls

Application Areas

The MDS-B-SPJ2-37 spindle drive unit is commonly used in CNC machine tools, particularly:

- Machining centers: For precise milling and drilling operations

- Lathes: For controlling the main spindle

- Grinding machines: For controlled grinding processes

It is compatible with Mitsubishi MELDAS CNC controllers and is often found in machines from manufacturers like Mazak and DMG Mori.

Function

The spindle drive unit precisely controls the main spindle’s speed and torque of a CNC machine. It enables:

- High rotational speed precision: For accurate machining

- Fast acceleration and deceleration: To optimize machining times

- Stable torque control: To ensure consistent cutting conditions

Common Errors and Issues

Typical problems with the MDS-B-SPJ2-37 spindle drive include:

- Overheating: Due to insufficient ventilation

- Spindle vibrations: Caused by faulty motor or cable connections

- Alarms and warnings: Displayed via 7-segment LEDs (for exact diagnostics, refer to the manual)