05.05.2025 by Viktor Siebert

Repair of the Mitsubishi MR-J2-60C-S100 AC Servo Drive – A Field Report

Obsolete Servo Drive Without Manufacturer Support

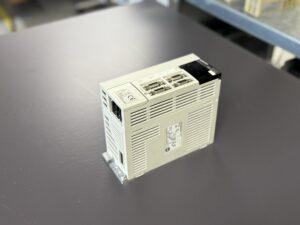

The Mitsubishi MR-J2-60C-S100 is a 600 W AC servo amplifier from the MELSERVO-J2 series. This product line was introduced in the 1990s and featured advanced capabilities for its time, such as built-in position control, automatic motor recognition, and support for absolute encoders. However, the MR-J2 series was discontinued in the mid-2000s, and Mitsubishi officially ceased support and spare part availability years ago. New replacement units are no longer available, and the manufacturer no longer offers repair services. For machine operators, this means that in case of failure, repair becomes the only viable alternative to complete system retrofitting.

Practical Case: MR-J2-60C-S100 Failure in a Machine

A medium-sized machine builder contacted us after one of their machines broke down due to a faulty MR-J2-60C-S100 drive. The drive was no longer functional and showed only an alarm code on its LED display. Since the drive was a critical axis control unit, the entire machine came to a standstill. Mitsubishi could no longer supply a replacement or offer repairs, which posed a significant challenge for the customer.

They reached out to our company — a specialist in industrial electronics repair. Our task was clear: restore the drive quickly and reliably so the machine could resume operation without delay.

Customer-Specific Solution: Development of a Repair Process

At the request of the customer, we developed a standardized repair procedure for the MR-J2-60C-S100. Based on in-depth analysis and failure patterns of the unit, we defined a flat-rate repair model, covering a comprehensive restoration of the device, including proactive replacement of aging components.

We also established a detailed test protocol that includes insulation testing, internal voltage checks, and full functional testing of all input/output control signals.

To verify performance under real conditions, we built a dedicated test bench for the MR-J2-60C-S100. This setup includes a compatible 600 W Mitsubishi servo motor with encoder, enabling us to simulate real-life load conditions. The unit undergoes automated test cycles with predefined movement profiles and error detection routines. This ensures the repaired unit will work flawlessly once reinstalled into the customer’s machine.

Reliable Performance: 0% Complaint Rate

Since we introduced this repair service, we have successfully refurbished numerous MR-J2-60C-S100 units — with a 0% complaint rate to date. All units passed our end-of-line testing and have been operating reliably in the field. We attribute this success to our preventive replacement strategy and our realistic, load-based test environment, which allows us to detect even hidden or intermittent defects.

More Info & Contact

To mentioned Mitsubishi Drive: Mitsubishi AC Servo Drive MR-J2-60c-S100

More details about our Mitsubishi repair services can be found here:

Mitsubishi drive Repair by Industrypart

We regularly repair similar models, including:

MR-J2-60C

MR-J2-60CT

MR-J2-60CP

MR-J2-60A

📞 Feel free to contact us with any questions about your Yaskawa drive technology.

Our expert team is happy to help!

Technical Specifications of the MR-J2-60C-S100

| Input voltage | 200–230 V AC, 50/60 Hz |

| Input phases | Usable with 1-phase or 3-phase AC |

| Input current | ~3.2 A (3-phase), ~4.8–5.5 A (1-phase 230 V) |

| Output | 3-phase PWM inverter, ~170 V, 0–360 Hz, ~3.6 A |

| Control features | Built-in positioning controller with point table logic |

| Communication | RS-232C (single) and RS-422 (multi-axis) |

| I/O interfaces | Digital I/Os, analog speed/torque inputs, alarms |

| Motor compatibility | Mitsubishi HC- / HA-series with encoder |

| Protection features | Full alarm/error system (A.10–A.52), dynamic braking |

Table 1: Technical highlights of the MR-J2-60C-S100 AC Servo Amplifier.

The drive can operate with either single-phase or three-phase input voltage and includes an internal motion controller capable of executing predefined point sequences. Communication is possible via RS-232C for PC setup or RS-422 for up to 32-axis networks. An extensive set of digital and analog I/Os allows integration into a wide range of machine control architectures.

Typical Applications for the MR-J2-60C-S100

During its production lifecycle, the MR-J2-60C-S100 was widely used across many industrial automation sectors, including:

- CNC machine tools: Axis control in turning, milling, and drilling machines.

- Packaging and printing equipment: For feeding, labeling, cutting, and conveyor axes.

- Robotics and pick-and-place systems: Controlling linear or rotary axes in assembly lines.

- Textile machines, semiconductor systems, and other OEM machinery requiring precise position control and compact servo systems.

Many machines built between the late 1990s and early 2000s still rely on these drives today, particularly in Japan and Asia, but also in imported or OEM-branded equipment.

Special Considerations and Challenges During Repair

Repairing the MR-J2-60C-S100 poses unique challenges due to the age of the devices, discontinued manufacturer support, and specific technical architecture.

Among the key considerations:

- Aging electronic components, such as capacitors or optocouplers, must be evaluated and often replaced as a preventive measure.

- Access to technical documentation and knowledge of Mitsubishi’s alarm codes (e.g., A.10 Undervoltage, A.12 Memory Error, A.16 Encoder Fault) is crucial for diagnostics and effective repair.

- Testing requires real load conditions, meaning that repairs must be validated using real motors and programmed test sequences.

- Spare parts availability is increasingly limited, requiring in-house reengineering or compatible substitutes in some cases.

Thanks to our expertise, experience, and specialized equipment, we are able to offer sustainable repairs of this legacy device — helping customers extend the service life of their existing equipment without needing costly and complex retrofits.