12.11.2025 by Viktor Siebert

Repair of a Fanuc A06B-6087-H126 Power Supply Module the Express Service within 48 Hours

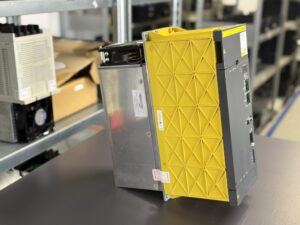

A customer personally delivered a defective Fanuc Power Supply Module A06B-6087-H126 to our repair center.

The machine was completely down, and a replacement from the OEM would have cost over €7000, with more than a week of lead time.

We accepted the unit as an express repair.

Initial testing revealed no visible damage, but the DC link was permanently shorted.

The IGBT module had failed, and the pre-charge and discharge circuits were thermally overloaded.

Because we maintain dedicated capacity for express cases, the module was immediately cleaned, documented, and brought to the test station.

Diagnostics, spare part preparation, and documentation ran in parallel.

The technicians disassembled the unit completely and checked all semiconductors, diodes, shunts, and capacitors.

After replacing the IGBT module, cleaning the board, and renewing the fan assembly, the unit was tested on a Fanuc test bench with simulated 230 V AC input.

Voltage, temperature, and gate signals were monitored continuously during testing.

After about six hours, the module operated stable, reached all setpoints, and showed no overcurrent or regulation errors.

Within 48 hours, the customer picked up a fully functional, documented, and verified power supply.

Such express repairs are only possible because we reserve a part of our capacity specifically for urgent cases.

Each repair follows standardized inspection and assembly checklists to ensure process reliability.

Every module is traceable and comes with a test report.

This approach reduces cost, downtime, and ensures high reliability at one fifth of the OEM price.

Preventive Maintenance for Customers

- Check and replace fans and filters every 12 months

- Replace capacitors every 5–7 years

- Regularly inspect connectors and DC bus cables

- Keep environment clean and below 40 °C ambient temperature

- Perform insulation test (500 V Megger) annually

- Record operating hours and temperature data

Conclusion

A Fanuc Power Supply Module can be repaired economically and reliably when handled by an experienced team with proper test equipment and original parts.

Through standardized procedures and preventive maintenance, unplanned downtime can be avoided and total cost of ownership significantly reduced.

To mentioned Fanuc Drive: Fanuc A06B-6087-H126 Power Supply Module

More details about our Fanuc repair services can be found here:

Fanuc drive Repair by Industrypart

📞 Feel free to contact us with any questions about your Fanuc drive technology.

Our expert team is happy to help!

Device Specifications:

| Specification | Value | Remark |

|---|

| Manufacturer | Fanuc Ltd. | Japan |

| Device Type | Power Supply Module (PSM) | For Fanuc α-Series Servo/Spindle Drives |

| Model Number | A06B-6087-H126 | DC bus converter 283–325 V DC |

| Input Voltage | 3-phase 200–230 V AC, 50/60 Hz | Mains input |

| Output Voltage | approx. 283–325 V DC | Supplies servo amplifier modules |

| Rated Power | approx. 27 kW | Depending on configuration |

| Control Method | PWM-controlled rectifier | With active current limiting |

| Cooling | Forced ventilation (fan unit) | Integrated temperature monitoring |

| Weight | approx. 12 kg | Without fans and mounting parts |

| Dimensions | approx. 380 × 180 × 120 mm | Standard size for PSM series |

| Manual Reference | Fanuc Maintenance Manual | Section: Power Supply Modules α-Series |

Application Environment & Compatible Equipment

The Fanuc Power Supply Module A06B-6087-H126 is part of CNC machine systems equipped with α-series servo and spindle amplifiers.

Typical users include DMG MORI, Mazak, Okuma, Fanuc Robodrill, Bridgeport, Hurco, and other manufacturers using Fanuc control systems such as Series 0i, 16i, 18i, 21i, and 31i.

It supplies multiple servo amplifier units (for example A06B-6079-H106 or A06B-6089-H105) via the internal DC bus.

The module is mounted inside the main control cabinet with forced cooling.

Maximum ambient temperature: 45 °C, protection class IP20.

Functional Description

The Power Supply Module provides the DC bus voltage for all connected servo and spindle amplifiers.

It converts the incoming 3-phase AC voltage into a stable DC voltage around 300 V DC.

Main features include:

- Rectification and DC bus stabilization

- Voltage and current monitoring

- Protection against overcurrent, overvoltage, and overtemperature

- Control and feedback communication with the CNC

- Built-in pre-charge and discharge circuitry

The control logic communicates via optically isolated interfaces to ensure safety and reliability.

Gate signal monitoring detects malfunctioning IGBT modules or control board failures immediately, protecting both drive and machine.

Alarm Messages & Troubleshooting

| Code | Error Description | Cause | Solution |

|---|

| AL-01 | Power Supply Unit Error | Fault in mains input or defective power section | Check input voltage, replace module if necessary |

| AL-03 | DC Bus Voltage Error | Overvoltage or undervoltage in the DC link | Inspect capacitors, rectifier, and input supply |

| AL-04 | Motor Power Line Overcurrent | Shorted IGBT module | Test transistors and gate driver |

| AL-05 | Inverter Overheat | Insufficient cooling, fan failure | Check fan, clean heat sink |

| AL-06 | Inverter Overload | Load exceeded design limit | Check mechanical load, verify parameters |

| AL-07 | Commercial Power Source Error | Input voltage outside tolerance | Verify line voltage and connections |

| AL-09 | Motor Winding Changeover Error | Malfunction in switching contactor | Test winding relay and wiring |

| AL-10 | Encoder Communication Error | Loss of communication with encoder | Check cable and connector integrity |

| AL-12 | Encoder Initialization Error | Initialization error at startup | Verify voltage, wiring, and encoder |

| AL-14 | Motor Overcurrent Error | Abnormal current in power module | Inspect IGBT module and control circuit |

| AL-20 | Motor Overheat | Thermal sensor triggered | Check fan, replace temperature sensor |

| AL-31 | Speed Over Error | Overspeed detected | Check encoder, motor load, and voltage |

| AL-32 | Speed Deviation Too Large | Speed feedback mismatch | Check servo tuning and mechanical binding |