12.07.2025 by Viktor Siebert

Alarm A.03 on Okuma MIV04-3-V1 Spindle Drive

Recently, a customer contacted us who operates several Okuma machines in his production facility. One of them, an Okuma LT10-M CNC lathe, began displaying Alarm A.03 on the MIV04-3-V1 spindle drive (1006-2254) during startup. At first, the error disappeared after turning the machine on and off a few times. However, when the alarm began to appear during operation, the customer became concerned and started looking for solutions.

The customer seeks a sustainable repair solution

Replacing the module was not an option for him. As someone who is environmentally conscious and actively involved in sustainability, his priority was repair over replacement. Through online research, he found our company. One of his key concerns was to know the repair cost in advance, and he found our transparent pricing and dedicated testing infrastructure highly credible.

He later told us that he had already made expensive mistakes in the past. The internet is full of companies offering parts without having any real technical understanding or in-house expertise. Others attempt repairs without proper testing capabilities. “I ask specific questions and insist on being properly advised,” said the environmentally responsible customer. For him, technical know-how, proper consultation and honesty were decisive factors.

Causes of Alarm A.03

Alarm A.03 indicates an overvoltage or undervoltage condition on the DC bus of the inverter unit. Common causes include:

- Unstable or low input voltage during startup

- Malfunction or aging of the MPS/MPR power supply unit

- Internal capacitor failure in the MIV04-3-V1

- Feedback or load-related issues during motor operation

Solutions and Prevention

If Alarm A.03 appears regularly, we recommend the following:

- Check the condition of the MPS/MPR power supply module

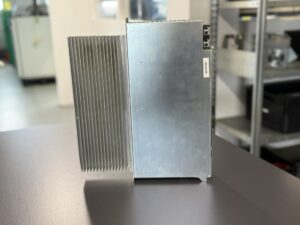

- Inspect fans and heat sinks for proper operation and cleanliness

- Have the MIV unit fully tested on a professional test bench

- Perform regular maintenance and preventive overhauls

- Test the unit under load to detect thermal or dynamic issues

Our repair process

Once the defective unit arrives at our facility, we carry out detailed documentation, disassembly, visual inspection and cleaning. The drive is then tested on an original system setup that simulates real operation. We analyze internal voltages, gate signals and the stability of the DC bus.

If necessary, we replace all critical components preventively, including power semiconductors, IGBTs, capacitors and internal relays. Finally, the unit goes through an extended load and endurance test before it is returned to the customer.

For more information about our Okuma repairs, please click here.

📞 Feel free to contact us if you have any questions regarding your Mitsubishi drive technology. Our experienced team is always ready to provide you with expert advice and support.

Technical Specifications (Device Data):

| Specification | Value |

|---|

| Model | MIV04-3-V1 |

| Part Number | 1006-2254-027-005 |

| Rated Power | 4.0 kW |

| Motor Type | VAC motor |

| Input Voltage | DC 300 V (supplied by MPS/MPR unit) |

| Control Power Supply | 24 VDC |

| Dimensions (H × W × D) | 380 × 60 × 325 mm |

| Weight | 5.7 kg (12.5 lb) |

| Compatible Control Card | ICB3 |

| Application | Spindle, M-tool spindle, sub spindle |

Alarm Messages and Troubleshooting

| Alarm Code | Meaning | Suggested Action |

|---|

| AL 03 | Inverter DC Bus Voltage Error | Check power supply |

| AL 04 | Motor Overcurrent | Replace motor, cables, or inverter unit |

| AL 05 | Overheat | Check operation conditions and ambient temp |

| AL 06 | Inverter Overload (Thermal) | Reduce load, check cooling system |

| AL 10 | Encoder Communication Error | Check encoder, cable, or inverter unit |

| AL 13 | Inverter Bridge Error | Replace unit |

| AL 20 | Motor Overheat | Check environment, fans, temperature sensor |

| AL 25 | Command Error | Check NC program and parameter settings |